The Comprehensive Guide to Auto Parts Manufacturers

The automotive industry is a significant sector of the global economy, characterized by its complexity and dynamic nature. The backbone of this industry is formed by auto parts manufacturers who create the essential components needed in vehicles. In this article, we will explore the role of auto parts manufacturers, their processes, and how they contribute to the success of the industry. Join us as we delve into the fascinating world of automotive components!

Understanding Auto Parts Manufacturers

Auto parts manufacturers are specialized businesses that design, produce, and distribute various components used in vehicles. These components range from simple screws to complex engine systems. Understanding their importance allows us to appreciate the innovation and effort that goes into creating the vehicles we rely on daily.

Key Functions of Auto Parts Manufacturers

- Design and Engineering: Manufacturers invest significantly in R&D to innovate and improve parts.

- Production: Utilization of advanced technologies helps in mass production while maintaining quality.

- Supply Chain Management: Efficient logistics ensures timely delivery of components to OEMs and retailers.

- Quality Control: Rigorous testing and quality assurance processes are vital to maintain safety standards.

The Role of Auto Parts Manufacturers in the Automotive Industry

Auto parts manufacturers are critical to the automotive supply chain. Their role goes beyond mere production; they are essential partners for original equipment manufacturers (OEMs) and aftermarket businesses. Let’s break down their contributions:

1. Supporting Innovation

The automotive sector is ever-evolving, with new technologies emerging every year. Manufacturers invest heavily in research and development to stay ahead, resulting in innovative products that enhance vehicle performance, safety, and efficiency.

2. Ensuring Quality and Safety

Safety is of utmost importance in the automotive world. Auto parts manufacturers adhere to strict regulations and standards, ensuring that all produced parts meet or exceed industry requirements. This focus on quality helps prevent failures and recalls, which can be costly for both manufacturers and consumers.

3. Creating Jobs and Economic Impact

The presence of auto parts manufacturers contributes significantly to local economies. They create numerous jobs ranging from engineering roles to assembly line positions. This economic activity fosters community growth and stability.

4. Facilitating Sustainability

As the globe shifts towards greener practices, many auto parts manufacturers are prioritizing sustainability. They implement eco-friendly processes and materials, reducing waste and energy consumption. This effort aligns with global initiatives to combat climate change.

Types of Auto Parts and Their Importance

Auto parts manufacturers produce a diverse array of components vital for vehicle operation and safety. Below are some major types of auto parts and their significance:

1. Engine Components

The engine is the heart of any vehicle. Components like pistons, crankshafts, and camshafts are essential for a vehicle's performance. High-quality engine parts directly correlate with fuel efficiency and overall power.

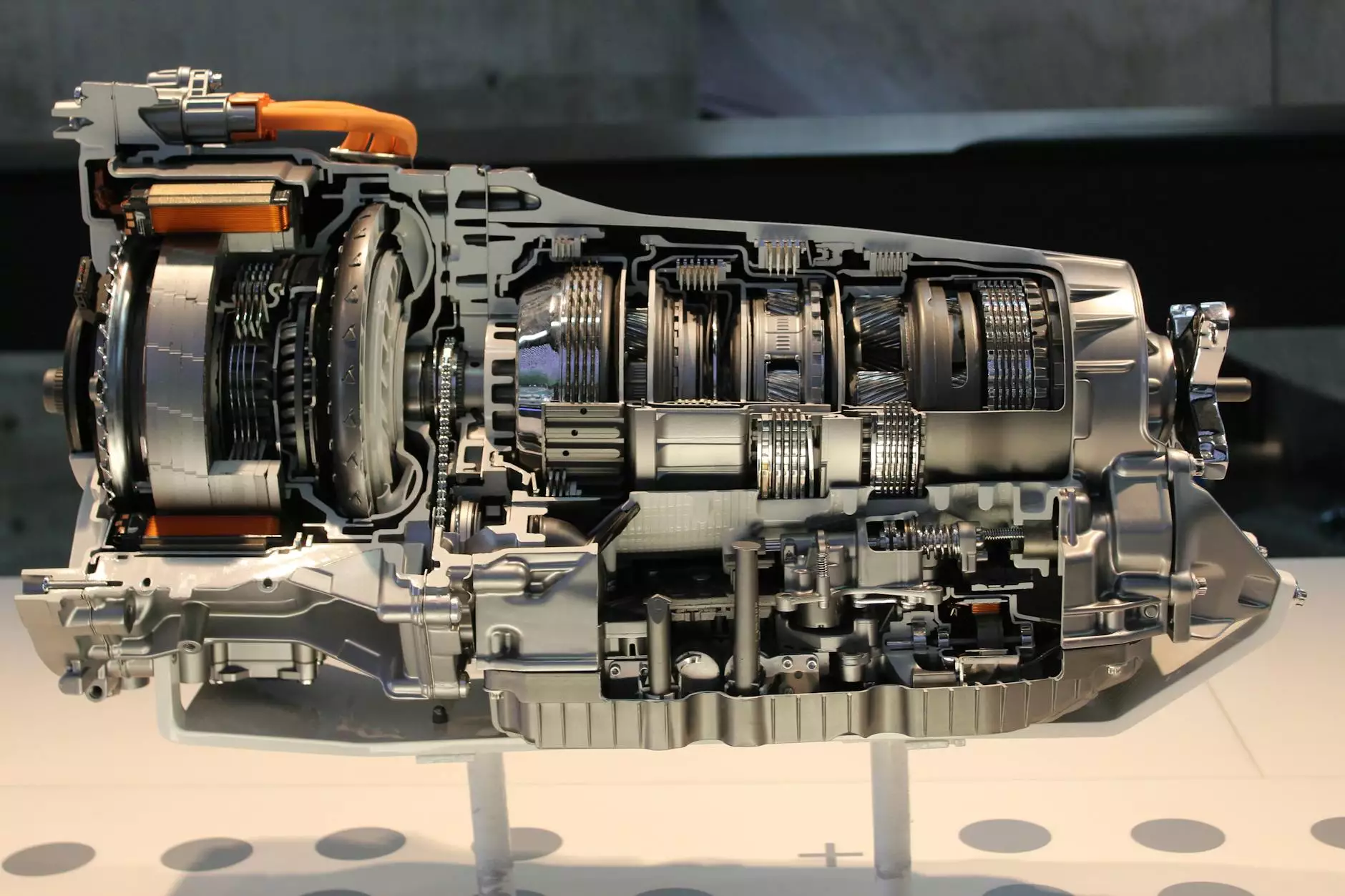

2. Transmission Parts

These parts are responsible for transferring power from the engine to the wheels. Components such as gears, clutches, and linkages play a crucial role in ensuring smooth gear transitions and enhancing driving experience.

3. Brake Systems

Safety cannot be compromised. Auto parts manufacturers produce brake pads, calipers, and rotors that ensure a vehicle can stop effectively, safeguarding passengers and other road users.

4. Suspension Systems

Suspension components such as shock absorbers and struts affect ride quality and vehicle handling. Quality manufacturing is essential in delivering safety and comfort during travel.

The Manufacturing Process of Auto Parts

The journey from concept to completion for auto parts manufacturers involves several stages:

1. Research and Development

This stage involves brainstorming and innovating new parts or improving existing ones. Engineers and designers collaborate to create prototypes and test their functionality.

2. Material Selection

Choosing the right materials is crucial for performance and durability. Manufacturers often use steel, aluminum, plastic, and composites, depending on the part’s requirements.

3. Production Techniques

Auto parts can be produced through various techniques, including:

- Die Casting: Commonly used for producing aluminum parts.

- Injection Molding: Ideal for plastic components.

- Machining: Precise parts are created by removing material from a solid block.

4. Quality Testing

Before reaching the market, products undergo extensive testing to ensure they meet safety and performance standards. This could involve physical tests, simulations, and inspections.

5. Packaging and Distribution

Once approved, parts are packaged for shipment. Efficient logistics systems are crucial to ensure timely delivery to distributors and retailers.

How to Choose the Right Auto Parts Manufacturer

1. Reputation and Experience

Look for manufacturers with a strong reputation and years of experience. Companies that have been in the industry often have established quality procedures and understand market needs.

2. Quality Assurance

Ensure that the manufacturer follows quality control procedures and holds relevant certifications (ISO, TS16949). This certification demonstrates a commitment to excellence.

3. Range of Products

A manufacturer that offers a wide variety of parts indicates versatility and expertise in multiple domains, providing a one-stop solution.

4. Customer Support

Assess the level of support provided. A responsive customer service team can be crucial for addressing issues or queries effectively.

5. Pricing and Flexibility

While price shouldn’t be the sole factor, finding a manufacturer that offers competitive pricing while maintaining quality is essential. Additionally, flexibility in production quantities and customization options is a plus.

The Future of Auto Parts Manufacturing

The landscape of auto parts manufacturers is continuously changing, driven by technological advancements and evolving market demands. Key trends include:

1. Technological Integration

As Industry 4.0 trends permeate manufacturing, technologies such as AI, IoT, and automation are set to transform production processes, leading to increased efficiency and reduced costs.

2. Electric and Autonomous Vehicles

The rise of electric and self-driving vehicles is reshaping parts manufacturing. This trend opens new opportunities and challenges for manufacturers to adapt and innovate accordingly.

3. Increased Focus on Sustainability

As environmental awareness rises, auto parts manufacturers are expected to further enhance their sustainability efforts, minimizing waste and developing eco-friendly products.

4. Globalization and Supply Chain Management

With the globalization of markets, manufacturers must adeptly manage complex supply chains to ensure consistent quality and timely delivery across geographic boundaries.

Conclusion

Auto parts manufacturers are integral to the automotive industry, playing a role that influences vehicle performance, safety, and innovation. Understanding their functions, processes, and the challenges they face enables a greater appreciation for the automotive ecosystem. As we move towards an increasingly technology-driven future, these manufacturers will continue to evolve, ensuring that we enjoy safe, efficient, and environmentally-friendly vehicles on the road.

For those looking for high-quality auto parts, consider exploring the offerings at imautoparts.com, where quality and customer satisfaction are the top priorities.